The Essential Guide to Spare Parts of Diesel Engines

Diesel engines are integral to various industries, powering everything from heavy machinery to transportation vehicles. Understanding the importance of spare parts of diesel engines can significantly impact the performance and longevity of the engine. In this guide, we delve into the different types of diesel engine parts, the role of suppliers, and how to choose the right components to ensure your engine runs efficiently.

Understanding Diesel Engines

Diesel engines function on the principle of compression ignition, which differs from gasoline engines that rely on spark ignition. This difference means that the repair and maintenance of diesel engines also require a unique set of spare parts designed specifically for their operation.

The Importance of Quality Spare Parts

When it comes to diesel engines, using high-quality spare parts is crucial. Inferior components can lead to numerous problems including decreased performance, increased fuel consumption, and potentially catastrophic engine failures. Here are some of the critical reasons why you should prioritize quality:

- Enhanced Performance: Quality parts ensure that your engine runs smoothly and efficiently.

- Longevity: Reliable components extend the life of your engine.

- Cost-Effective: Investing in quality reduces the frequency of replacements and repairs, ultimately saving you money.

- Safety: Durable parts contribute to safer operation, reducing the risk of breakdowns that could pose hazards on the road.

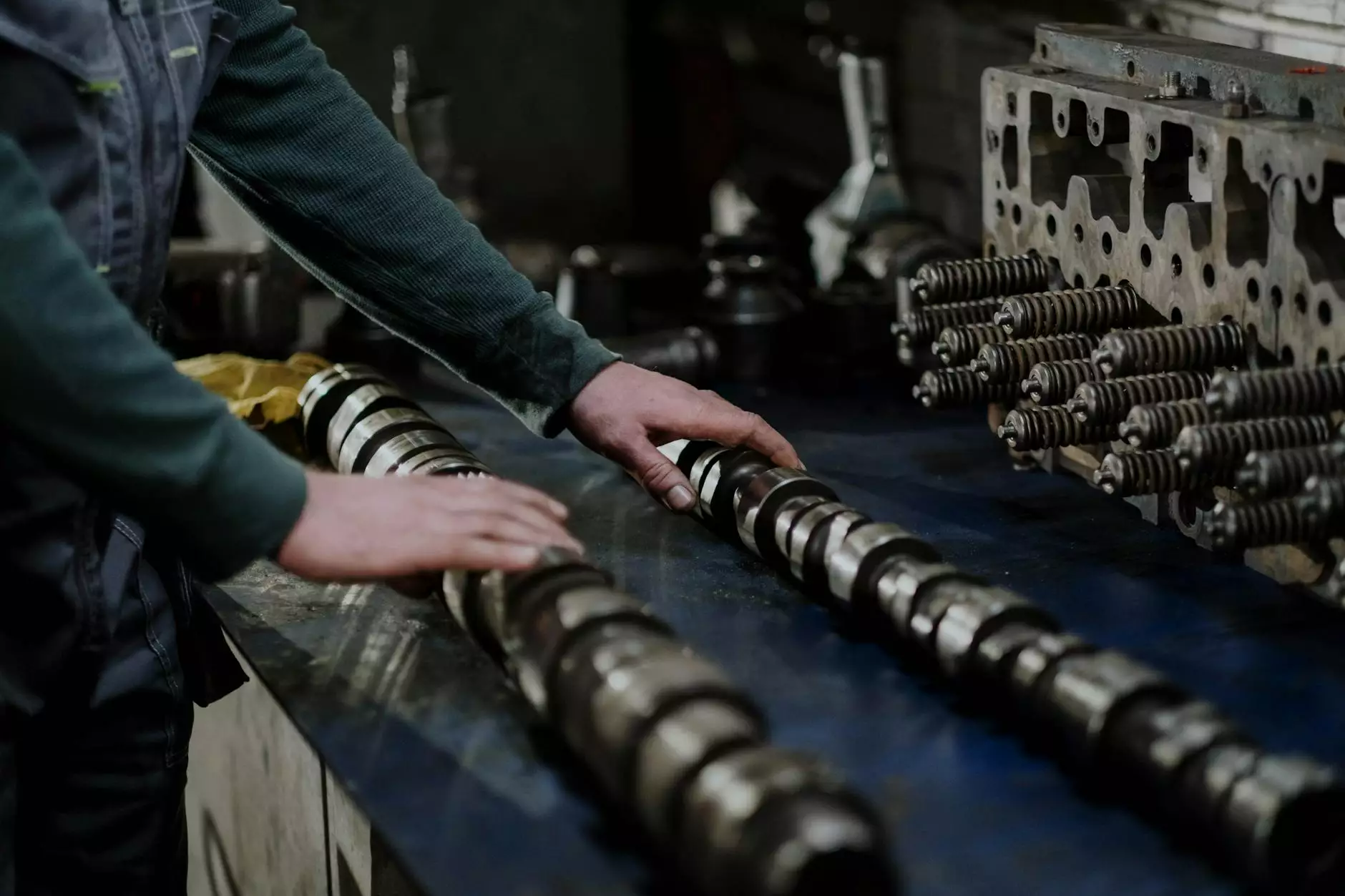

Common Spare Parts for Diesel Engines

There is a vast array of spare parts of diesel engines available in the market. Here are some of the most common components to consider:

1. Fuel Injectors

Fuel injectors play a vital role in delivering the right amount of fuel into the combustion chamber. They must be replaced when they begin to fail to maintain optimal engine performance.

2. Oil Filters

Regular oil changes are essential for the health of a diesel engine. Quality oil filters remove contaminants, ensuring the engine runs cleanly.

3. Air Filters

To prevent dirt and debris from entering the engine, air filters need to be replaced periodically, especially in harsh operating conditions.

4. Gaskets and Seals

Gaskets and seals are essential in preventing leaks in the engine. A high-quality gasket can maintain pressure and temperature, essential for an efficient diesel engine.

5. Piston Rings

Piston rings are crucial for maintaining combustion chamber pressure and controlling oil consumption. Worn rings can lead to increased oil consumption and exhaust smoke.

6. Turbochargers

Turbochargers enhance engine power and efficiency. It’s essential to ensure that they are functioning correctly, as a faulty turbo can dramatically impact performance.

Choosing the Right Spare Parts Suppliers

When it comes to sourcing spare parts of diesel engines, selecting the right supplier is critical. Here are some tips on how to make the best choice:

- Reputation: Research the supplier’s reputation within the industry. Read reviews and testimonials to gain insight into their reliability.

- Quality Assurance: Ensure the supplier provides quality parts that meet industry standards and specifications.

- Range of Products: A good supplier will offer a comprehensive range of spare parts, allowing for one-stop shopping.

- Customer Support: High-quality customer service can make a significant difference, especially when troubleshooting issues.

- Pricing: While quality is paramount, ensuring competitive pricing without compromising on quality is also crucial.

Benefits of Partnering with Reliable Suppliers

Teaming up with reputable suppliers can yield several advantages:

- Timely Delivery: Reliable suppliers ensure you receive your parts on time, preventing unnecessary downtime.

- Expert Guidance: Experienced suppliers can provide insights into which parts will work best for your particular engine model.

- After-Sales Support: Quality suppliers often offer support after the sale allowing you to resolve any potential issues quickly.

Maintenance Tips for Diesel Engines

To maximize the lifespan and efficiency of your diesel engine, regular maintenance is paramount. Here are some actionable tips:

- Regular Oil Changes: Change the oil according to the manufacturer's recommendations to ensure engine lubrication.

- Inspect Filters: Regularly check and replace air and oil filters to maintain optimal performance.

- Monitor Engine Performance: Keep an eye on engine performance metrics and address any abnormalities immediately.

- Scheduled Servicing: adhere to a strict servicing schedule, conducting professional checks to identify issues before they escalate.

Future Trends in Diesel Engine Technology

The diesel engine industry is ever-evolving, with technology continually advancing. Here are some future trends to watch:

- Fuel Efficiency: Innovations aimed at improving fuel efficiency are paramount as industries continue to seek greener solutions.

- Emission Control: Stricter regulations are driving the development of technologies that minimize harmful emissions.

- Smart Engine Technology: Digital technologies and IoT are being integrated into diesel engines, providing valuable data for maintenance and efficiency optimization.

- Alternative Fuels: Research into Bio-diesel and other alternative fuels may reshape the future of diesel engines.

Conclusion

Investing in quality spare parts of diesel engines and choosing the right suppliers can make a significant difference in the performance, efficiency, and longevity of your diesel engine. Regular maintenance and staying informed about industry trends further enhance these benefits. Ultimately, a well-maintained diesel engine powered by quality components is key to operational success in any sector.

For more insights and to explore a wide range of spare parts, visit client-diesel.com. Your engine deserves the best, and with the right knowledge and resources, you can ensure it gets precisely that.