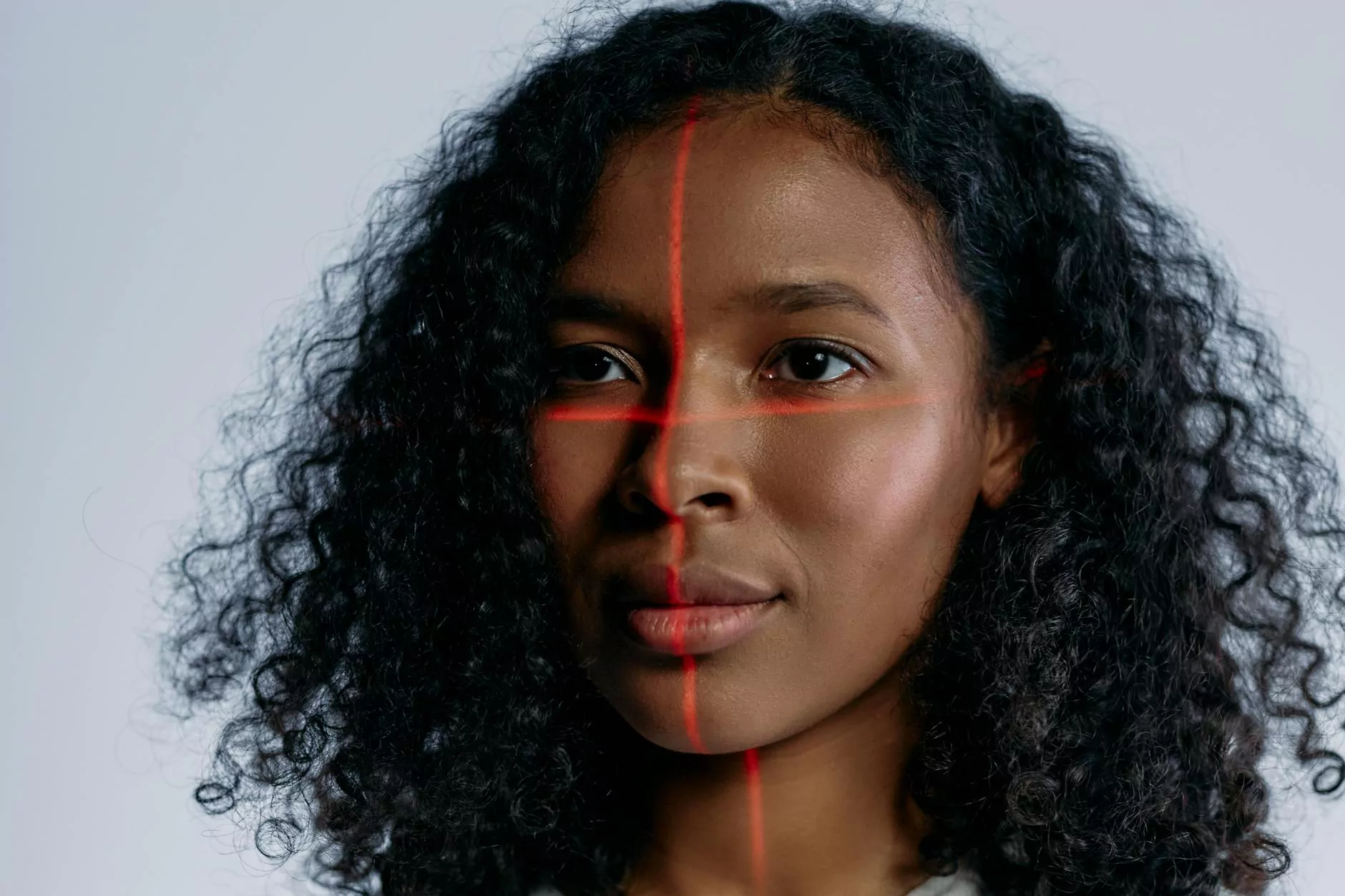

Selective Laser Sintering (SLS) Services

In the world of manufacturing, staying ahead of the competition means adopting innovative technologies that can deliver fast and reliable results. One such technology that has revolutionized the industry is Selective Laser Sintering (SLS).

The Power of SLS for Metal Fabricators

Metal fabricators are constantly seeking ways to streamline their processes and deliver exceptional quality products to customers. With the advent of SLS, metal fabricators now have access to cutting-edge 3D printing technology that allows them to create intricate parts and components with ease.

At QuickParts, we offer comprehensive selective laser sintering services that cater to the needs of metal fabricators. With our state-of-the-art SLS machines, we can transform your digital designs into physical objects using high-quality metal powders.

The SLS Process Explained

Selective Laser Sintering involves a unique additive manufacturing process that utilizes a high-powered laser to selectively fuse metal powders together. The process starts with a powdered material, typically a metal such as stainless steel or titanium, which is spread in thin layers onto a build platform.

Once the first layer is applied, the laser beam traces the desired shape onto the surface of the powder, sintering the particles together. The build platform then lowers by one layer thickness, and a new layer of powder is spread on top. This process is repeated layer by layer until the final object is created.

The Advantages of SLS for Metal Fabricators

One of the biggest advantages of using SLS technology for metal fabrication is the ability to create complex geometries and intricate designs that traditional manufacturing methods cannot achieve. The layer-by-layer approach allows for precise control over the manufacturing process, resulting in finished parts that meet rigorous quality standards.

SLS also offers exceptional design freedom, as it eliminates the need for support structures usually required in other manufacturing methods. This means that even the most complex shapes can be produced without the constraints of traditional fabrication techniques.

Furthermore, selective laser sintering enables the production of functional prototypes and end-use parts without the need for expensive tooling. This significantly reduces both the cost and lead time associated with traditional manufacturing processes.

3D Printing with SLS

Aside from its utilization in metal fabrication, SLS has also become a go-to method for 3D printing enthusiasts. The flexibility and versatility offered by this technology make it an ideal choice for bringing creative ideas to life.

Whether you are an architect designing intricate models, an artist exploring new forms, or a hobbyist experimenting with custom creations, SLS can turn your digital designs into tangible objects with incredible precision and unmatched detail.

Why Choose QuickParts for SLS Services?

When it comes to Selective Laser Sintering services, QuickParts is an industry leader. With years of experience and a commitment to delivering exceptional results, we have become the trusted partner for metal fabricators and 3D printing enthusiasts.

Here's what sets us apart:

Advanced Technology

At QuickParts, we stay at the forefront of technology. We have invested in state-of-the-art SLS machines that are capable of producing high-quality and accurate parts. Our team of experts continuously monitors and maintains our equipment to ensure optimal performance and reliability.

Extensive Materials Selection

We understand that different projects require different materials. That's why we offer an extensive range of metal powders for you to choose from. Whether you need stainless steel, titanium, or aluminum, we have the right materials to meet your specific requirements.

Fast Turnaround Time

Time is essential in business, and we recognize the importance of meeting deadlines. With our efficient production process and dedicated team, we strive to provide quick turnaround times without compromising on quality. You can trust us to deliver your SLS parts promptly.

Superior Quality Control

Quality is our top priority. We employ strict quality control measures throughout the entire manufacturing process to ensure that every part meets our high standards. From material selection to post-processing, our team meticulously inspects and tests each component, guaranteeing that you receive parts of exceptional quality.

Competitive Pricing

Our selective laser sintering services are not only of top-notch quality but also competitively priced. We believe that cutting-edge technology should be accessible to all, which is why we strive to offer affordable solutions without compromising on performance or service.

In Conclusion

Whether you are a metal fabricator looking to enhance your manufacturing capabilities or a 3D printing enthusiast seeking the best technology to bring your designs to life, QuickParts' selective laser sintering services are the answer. With our advanced technology, extensive materials selection, fast turnaround time, superior quality control, and competitive pricing, we are your trusted partner in achieving exceptional results.