Boost Your Business with 3D Printing

When it comes to Metal Fabricators and staying ahead in the highly competitive business landscape, embracing cutting-edge technologies is essential. In today's digital era, one such revolutionary technology that has gained significant prominence is 3D printing. QuickParts.com, the leading provider of metal fabrication solutions, understands the immense power that 3D printing brings to the table. In this comprehensive article, we will explore how 3D printing can transform your metal fabrication business and help you achieve unparalleled success.

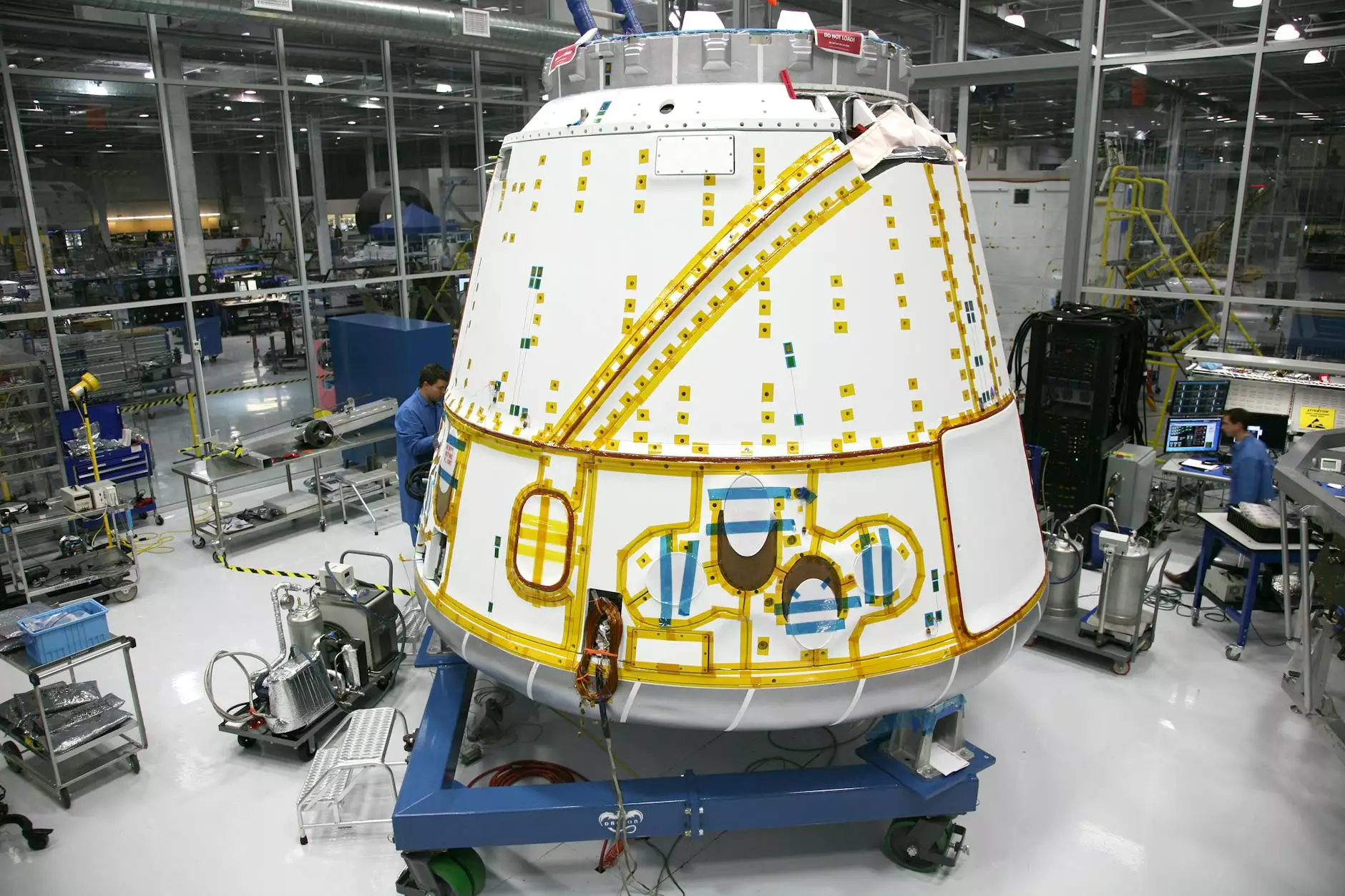

The Power of 3D Printing in Metal Fabrication

Traditional metal fabrication methods involve extensive manual labor, specialized tooling, and lengthy production cycles. However, with the advent of 3D printing, metal fabricators can enjoy numerous benefits that lead to faster, more efficient, and cost-effective manufacturing processes.

At QuickParts.com, we leverage state-of-the-art 3D printing technology to streamline metal fabrication services. By harnessing the power of Computer-Aided Design (CAD) and Additive Manufacturing (AM), we empower businesses to unlock new possibilities and revolutionize their production capabilities.

Unrivaled Precision and Customization

One of the key advantages of 3D printing in metal fabrication is the ability to achieve unrivaled precision and customization. With traditional methods, fabricators often face limitations in shape complexity, resulting in compromised designs and compromised end products.

However, with 3D printing, businesses can bring even the most intricate and complex designs to life. The layer-by-layer additive manufacturing process allows for the creation of highly detailed and customized metal parts that meet the specific requirements of each project.

Whether it's producing prototypes, one-off designs, or manufacturing complex geometries, QuickParts.com's 3D printing capabilities ensure that your metal fabrication business stays at the forefront of innovation.

Speeding up Production and Reducing Costs

Time is money in the world of metal fabrication. Manual processes are often time-consuming, labor-intensive, and prone to errors. These inefficiencies not only delay production but also significantly impact overall costs. This is where 3D printing comes to the rescue.

With QuickParts.com's 3D printing solutions, businesses can benefit from significantly reduced production times. By eliminating the need for tooling, complex fixture creation, and reducing assembly steps, 3D printing offers an unmatched speed advantage over traditional manufacturing methods. This allows you to meet tight deadlines, take on more projects, and ultimately propel your business forward.

Moreover, by minimizing material waste and optimizing production cycles, 3D printing reduces costs associated with scrap and rework. Whether you are a small business or an established enterprise, this means increased profitability and a better return on investment.

Enhancing Design Iteration and Flexibility

Design iterations and flexibility play a crucial role in bringing innovative products to market swiftly. Traditional metal fabrication methods often require additional time and expenses to modify designs once they have been implemented in the production process. 3D printing provides a game-changing solution.

QuickParts.com's 3D printing enables easy design modifications without the need for costly tooling changes or production line shutdowns. This flexibility empowers businesses to iterate quickly, minimize time-to-market, and stay ahead of the competition.

With 3D printing, you can explore various design concepts, test prototypes, and make modifications on-the-fly, leading to efficient product development and enhanced customer satisfaction.

Embracing Sustainability and Eco-Friendliness

In today's environmentally conscious world, sustainable manufacturing practices have become a top priority. Traditional metal fabrication processes often generate significant waste and consume excessive energy. However, 3D printing presents a greener alternative.

QuickParts.com is committed to environmental sustainability. By leveraging 3D printing in metal fabrication, we significantly reduce material waste, energy consumption, and carbon emissions. The precise deposition of materials ensures optimized material utilization, making 3D printing a far more eco-friendly choice compared to traditional methods.

By choosing QuickParts.com's 3D printing services, you contribute to a cleaner, greener future while enhancing your business's reputation as an environmentally responsible organization.

Unlocking Innovation and Business Growth

3D printing has emerged as a catalyst for innovation, propelling businesses towards unparalleled growth and success. As pioneers in the field of metal fabrication, QuickParts.com understands the transformative power of this technology.

By embracing 3D printing, you unlock endless possibilities and open new avenues for creativity, flexibility, and profitability. Whether you are in the automotive, aerospace, healthcare, or any other industry that requires high-quality metal fabrication, integrating 3D printing into your business can give you a significant competitive edge.

Join hands with QuickParts.com today and harness the full potential of 3D printing in metal fabrication. Empower your business to create stunning designs, optimize your production processes, and surpass customer expectations.

Conclusion

Embracing 3D printing technology offers Metal Fabricators a game-changing advantage in today's fast-paced business landscape. QuickParts.com, with its expertise and experience in metal fabrication, offers the perfect partnership to help you unlock the full potential of 3D printing.

Discover a world where precision, customization, speed, flexibility, sustainability, and innovation converge. Choose QuickParts.com for all your metal fabrication needs, and witness your business soar to new heights.